Amid the strong atmosphere of autumn and the loud sound of “Battle Drums”, affiliated enterprises of Shandong Heavy Industry Group (the Group) are working hard, quickening the pace to make progress, and speeding up for the annual business goals. They are working at full capacity to ensure production and improve quality and efficiency, fully igniting the enthusiasm for “Fighting in Q4”. This becomes the most brilliant landscape of the Group in the golden autumn.

Weichai Lovol Intelligent Agriculture Assists in Autumn Farming Production.

At present, it is the critical stage for "Autumn Harvest, Autumn Sowing, Autumn Land Preparation" (Autumn Farming) agricultural production. To fully ensure the supply of high-end intelligent agricultural machinery products, Weichai Lovol Intelligent Agriculture has organized to carry out the special campaign of "Improving Quality, Greeting High Yield" in the peak-season production, fully sounding the clarion of charge for “Fighting in Q4”.

In Weichai Lovol’s tractor production workshop, there is a busy scene where the front-line workers are devoting themselves to the stressful and busy work. The intelligent production line is in full swing for meeting orders and ensuring supply. It helps improve the production and delivery capacity of high-end intelligent products such as power shift tractor. So far, the workshop’s daily capacity for production of various types of tractors has exceeded 300 units. In the logistics shipping zone, the agricultural machinery products from the production line are parked on both sides in an orderly manner, and high-end agricultural machinery such as large-horsepower intelligent tractor and Lovol compound drill seeder are loaded onto transport vehicles, shipped out one after another, and delivered to the end users, injecting new momentum into the Autumn Farming production.

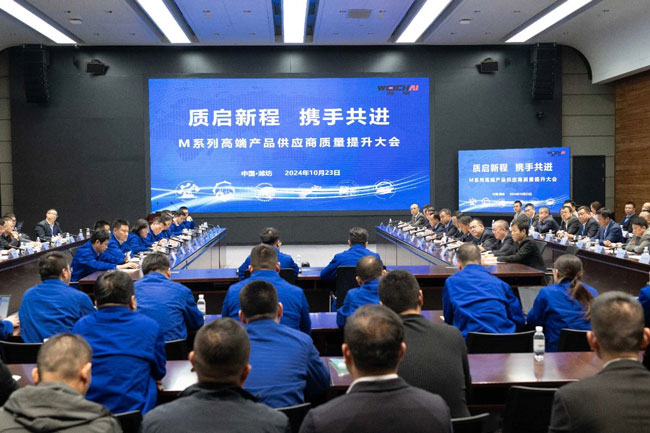

Weichai Launches Supplier Quality Improvement Campaign

On October 23, Weichai Group convened a supplier quality improvement conference for M-series large-bore high-end engine. More than 70 suppliers attended the meeting and listened to the reports on the market planning and development of Weichai M-series products, product quality performance and supplier auditing. At the meeting, supplier representatives made remarks. Weichai and supplier representatives signed the Commitment Letter on Quality Improvement of Weichai M-series High-end Products.

The meeting emphasized that the majority of supplier partners should maintain strategic consistency with Weichai, insist on the principle of win-win cooperation, and strengthen technical exchanges and collaborative innovation, in order to establish a community for shared interests, future, and value, and to jointly explore the market, foster brands, and lead the industry. Supplier partners are supposed to deepen collaboration in quality management, jointly create a world-class excellent brand for M-series high-end products, and jointly bring more values for global customers.

Sinotruk Promotes the Improvement of Product Quality and Efficiency

Quality is the life of a product, innovation is the soul of an enterprises, and cost reduction is an eternal theme. Sinotruk focuses on “Fighting in Q4” and continuously intensifies and accelerates the management improvement campaign "Quality, Innovation and Cost Reduction". It has rolled out a policy portfolio for cost reduction and efficiency increase, specified the tough tasks for cost reduction through procurement technology in the entire supply chain, shattered the cooperation barriers among business, technology and supplier, and kept improving the model for supplier centralization and cost standardization. As a result, it has achieved lean cost reduction in the whole value chain internally and externally from vehicle positioning to product selection and then to supplier collaboration.

Sinotruk continuously carries out quality management improvement campaign and promotes zero-defect quality transformation. In Jinan Commercial Vehicle Manufacturing Company, the "Quality Red and Black List" system, which is based on multiple quality indicators such as after-sales feedback, process discipline inspection, quality gate inspection and offline review, helps effectively promote the continuous improvement of assembling quality control ability, and the rolled throughput yield (RTY) of products keeps rising. Employees unanimously said: "Whenever I see the list, it reminds me that I should keep stressing the quality in my heart."

Business license

Business license